Inspection of steam generator tubes

Over more than 40 years, Intercontrôle has inspected more than 5 million steam generator tubes in nuclear reactors.

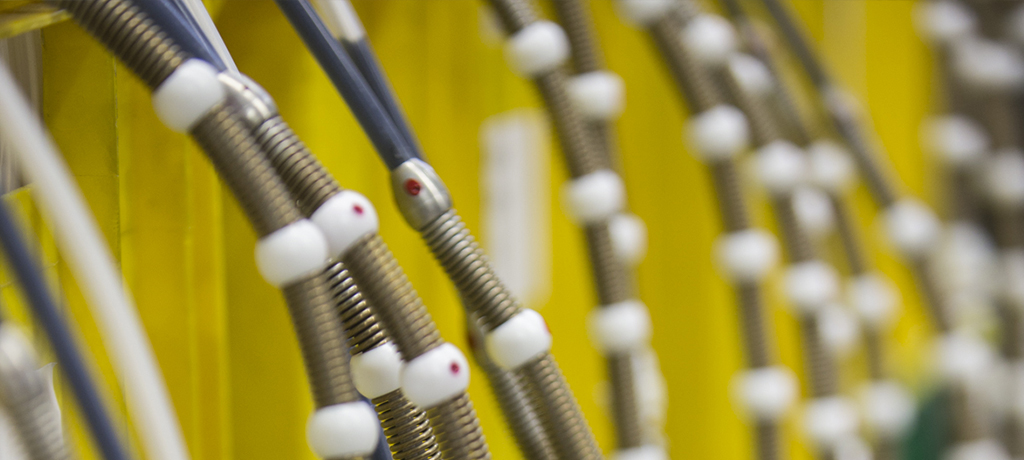

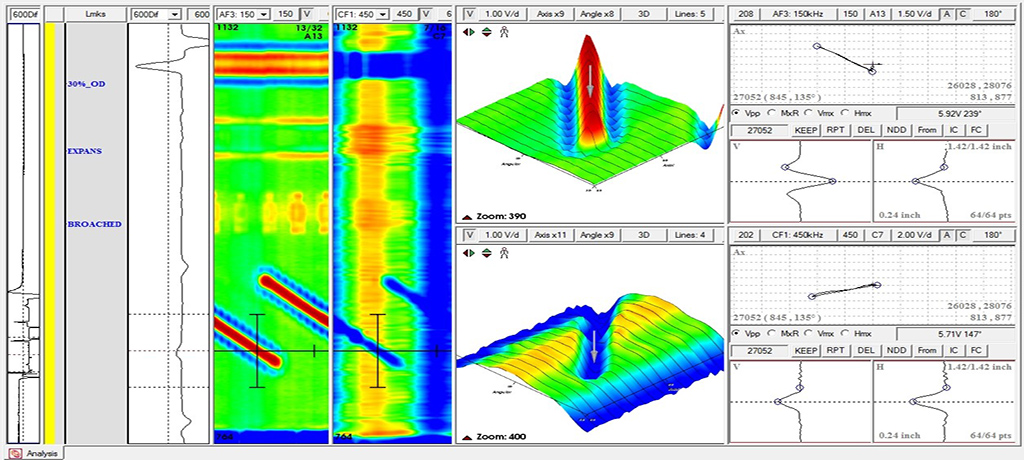

This examination, which is made using the eddy current testing method (ET) and the EXACT inspection chain, consists of moving an internal probe along all or part of the length of the inside of the tube being inspected in order to detect any indications.

The EXACT chain and the acquisition of the inspection data are remotely controlled from a shelter located outside the reactor building.

The data is sent in real time over a satellite link to our site near Paris, where our team of analysts carries out an on-site remote data analysis using various processing and analysis software applications.

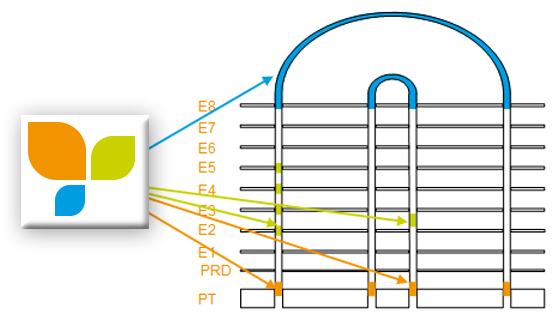

The diagram below shows the different areas that are inspected in the steam generator tubes of nuclear reactors, and the corresponding methods and techniques.

Technical Inspection

- Internal axial probes are used to detect defects along the entire length of the tube

- Internal rotating probes are more sensitive and can characterise defects in specific zones where degradation is expected

- Mixed axial / phased array internal inspection probe combine, in a single pass, the detection of defects along the entire length of the tube and the characterisation of defects in specific zones where degradation is expected.