Reactor pressure vessel inspection with the In-Service Inspection Manipulator (MIS)

Over more than 40 years, Intercontrôle has inspected more than 350 nuclear reactor pressure vessels.

We inspect pressure vessels of all the reactors in France and Belgium.

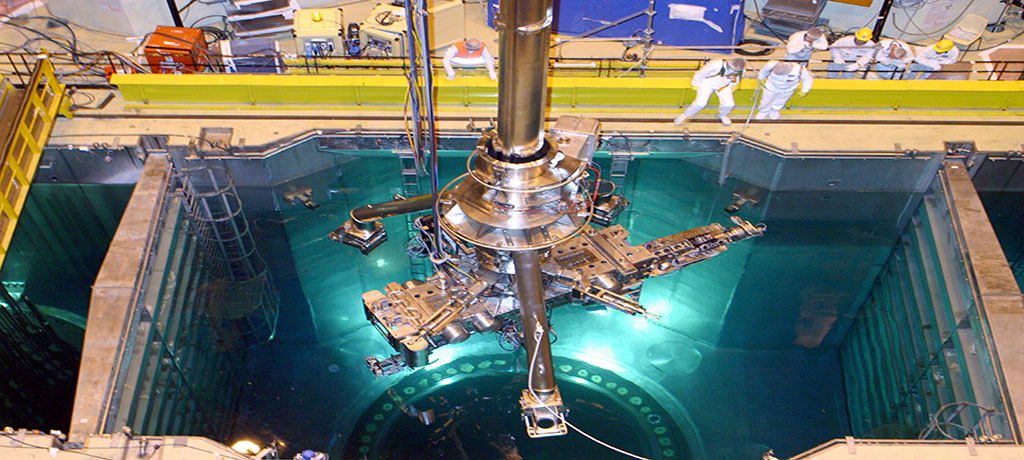

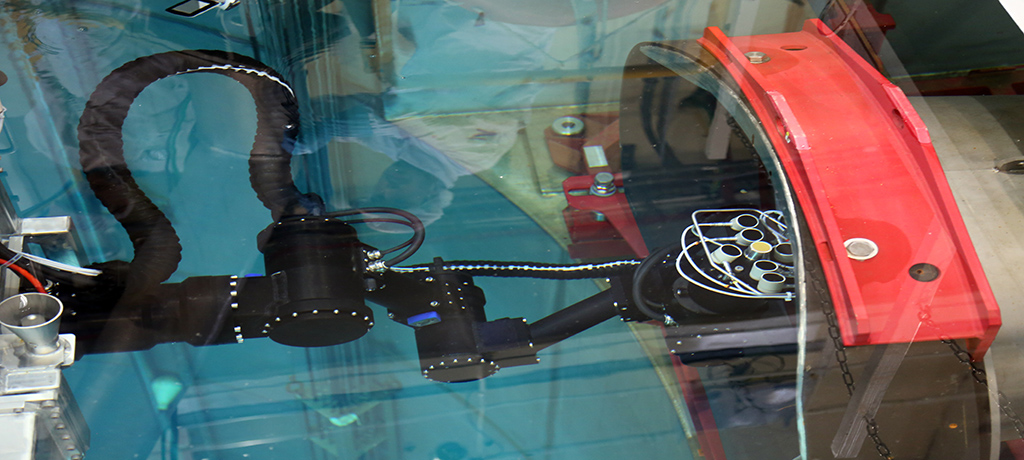

These inspections are made using the MIS, or in-service inspection manipulator, a 12-tonne robot measuring 12 metres in height, which supports and positions the tools used to inspect the pressure vessel to a precision of 1 millimetre.

The MIS is remotely-controlled from outside the reactor building, as are the acquisition, processing and analysis of the data.

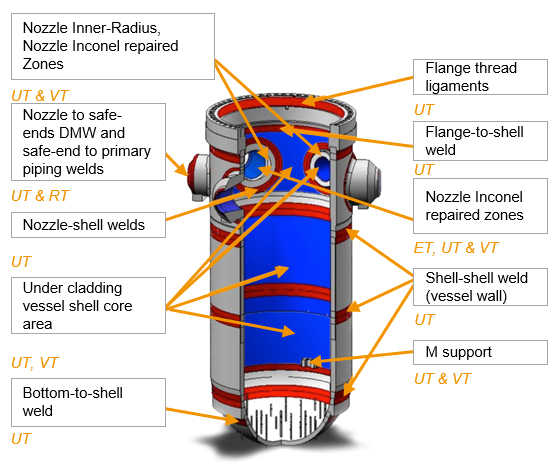

The diagram below shows all the inspected parts of the pressure vessel and the NDT methods used : ultrasonic testing (UT), radiography testing (RT), visual testing (VT) and eddy current testing (ET).