Nuclear Services

Les interventions sont réalisées à l'aide de la MIS, Machine d'Inspection en Service

In-service inspection of nuclear reactors: Using our experience to work for you.

Intercontrôle is specialised in the In-Service Inspection by automated Non Destructive Testing of the nuclear Pressurised Water Reactors primary circuit components.

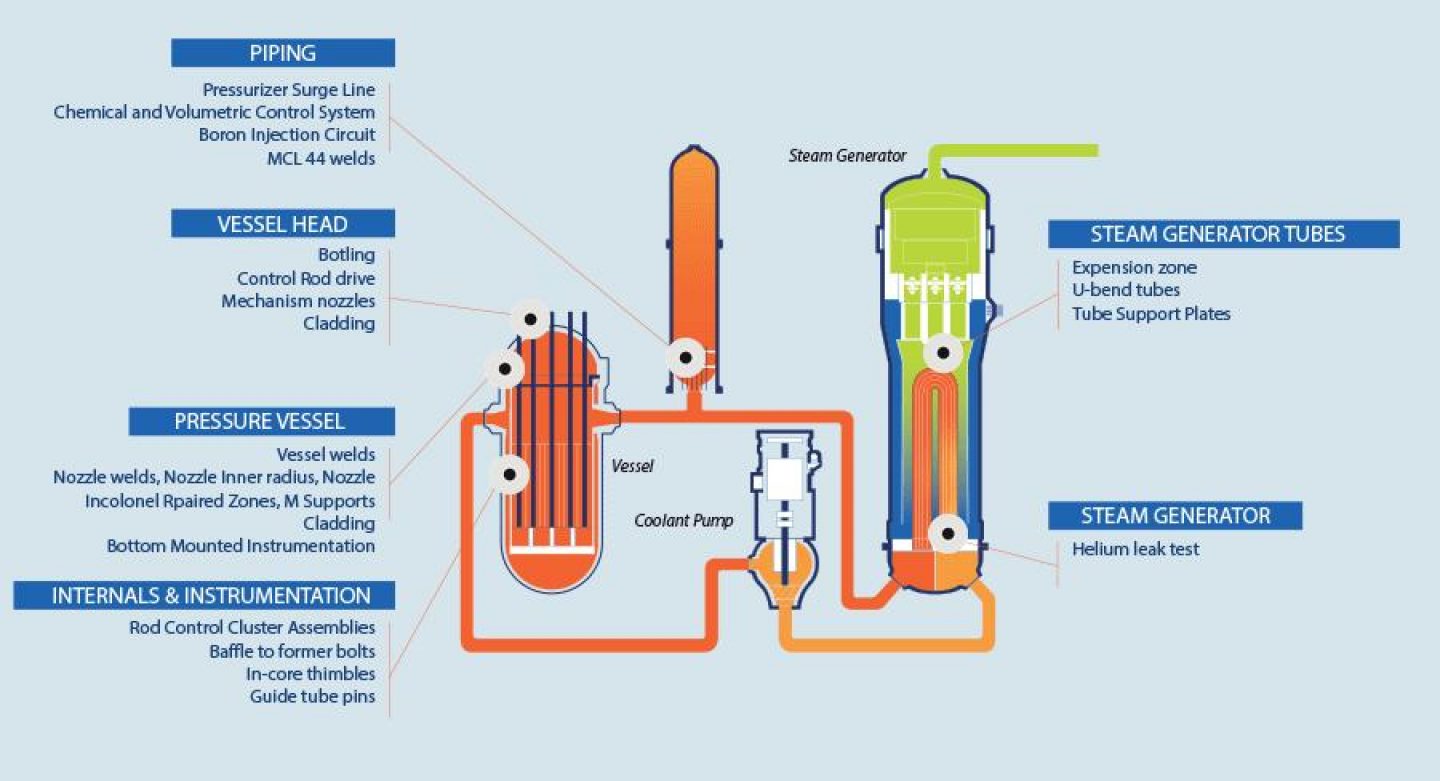

Our inspections mainly cover the reactor pressure vessel and the steam generator tubes, but they can also be applied to all the other primary components that are important to the safety of the reactor.

This diagram of a nuclear boiler shows the components that we inspect.

Codes and standards

Methods and equipment qualified to the applicable codes (RSE-M, ASME)

Nuclear reactor pressure vessel in-service inspection

Inspection of nuclear reactor steam generator

Development and qualification of equipment

Development and qualification of specific NDT equipment: Using our expertise to work for you

100

on-site operations per year

180

operators

155

COFREND-certified operators according to the European standard EN ISO 9712